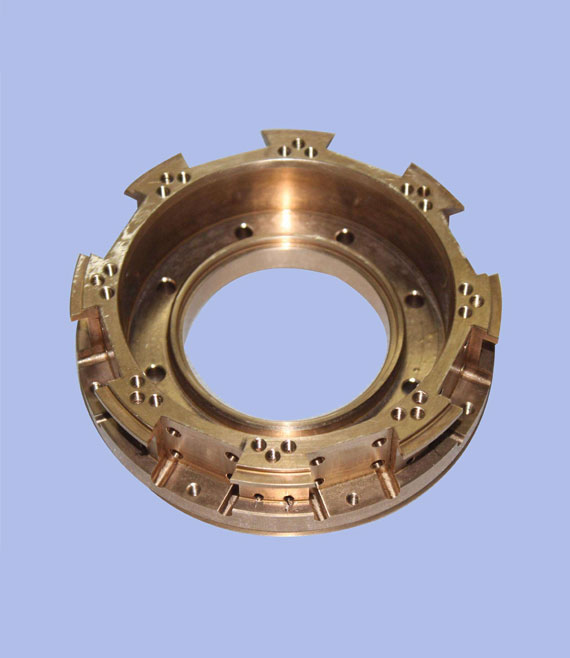

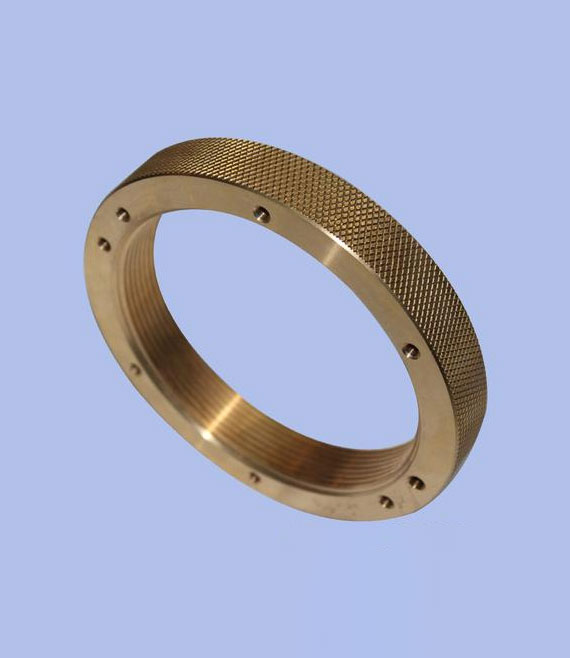

Brass also offers specific advantages that simplify and improve the process of CNC milling. Unlike many other metals with similar material properties, brass offers excellent machinability: many of its grades can be effectively penetrated by cutting tools, chipping easily while being relatively easy to shape. Because of this, brass can be machined more than three times faster than iron or steel.

Why choose us as manufacturer on Brass CNC milling?

- Experience – Our machinists have profound knowledge and experience as they handle different projects from different industries. They are talented in handling complex issues without compromising quality and precision.

- Advanced equipment – We have horizontal and vertical milling machines to give various detailed cuts in brass and steel metal components. We also feature a 5-axis CNC milling that increases our efficiency during production.

- Fast turnaround – With CNC milling equipment, you can expect us to provide you with a quick turnaround and on-time delivery.

- Cost – As an experienced manufacturer we know how to assist our customers to design and build the most cost effective components, our metal manufacturing capacities and equipment also helps us to achieve it. Especially for the parts manufactured based on brass extrusions, our expertise ensure us to work on material at low cost.

If you are looking for manufacturing for your precision brass components, feel free to contact us and request a free quote. Our team will be happy to help you.

Benefits of Brass CNC Milling

• Machinability

• Corrosion resistance

• Strength-to-weight ratio

• Electrical conductivity

• Anodization potential

• Recyclability

The Machinability Of Brass CNC Milling

One of the main reasons why engineers choose brass for their machined parts is because, quite simply, the material is easy to machine. While this would appear to be more of a benefit for the machinist manufacturing the part, it also has significant benefits for the business ordering the part, as well as the end-user that will eventually use it.

Because brass chips easily, and because it is easy to shape, it can be cut quickly and accurately with CNC machine tools. This has some important consequences: firstly, the short timeframe of the milling job makes the process cheaper (because less labor is required from the machinist and less operating time is required from the machine itself); secondly, good machinability means less deformation of the part as the cutting tool goes through the workpiece. This can allow the machine to meet tighter tolerances (as low as ±0.025 mm) and leads to higher accuracy and repeatability.

The Corrosion Resistance Of Brass CNC Milling

Different brass grades differ greatly in their resistance to corrosion — the degree to which they can withstand oxidization and chemical damage. Fortunately, some of the most popular grades for CNC milling are the most resistant. 6061, for example, offers excellent corrosion resistance, as do other alloys on the lower end of the strength spectrum. (Strong brass alloys may be less resistant to corrosion due to the presence of alloyed copper.)

Strength-to-weight ratio

Brass has desirable physical properties that make it ideal for both mechanical and aspect parts. Two of the most important are the metal’s high strength and its lightweight, both of which make the material favorable for critical parts such as those required in the aerospace and automotive industries. Aircraft fittings and automotive shafts are two examples of parts that can be successfully machined with brass.

However, different grades of brass serve different purposes. Because of their favorable strength-to-weight ratio, general-use grades like 6061 can be used for a wide variety of parts, while notably high-strength grades like 7075 may be preferred in aerospace and marine applications.

Electrical conductivity

CNC machined brass parts can be useful for electrical components due to their electrical conductivity. Though not as conductive as copper, pure brass has an electrical conductivity of about 37.7 million siemens per meter at room temperature. Alloys may have lower conductivities, but brass materials are significantly more conductive than, for example, stainless steel.